This is the view looking down the main street from the station. |

A rectangular Bizen plate is the perfect canvas for sushi. The local sushi bar uses only Bizenyaki tableware for its fish dishes, as well as for sake and soy sauce. |

|

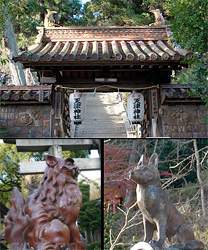

A shrine in Bizen. It is a little different from the usual shrines found all over Japan in that its guardian figures and even its rooftiles are made from Bizenyaki.

|

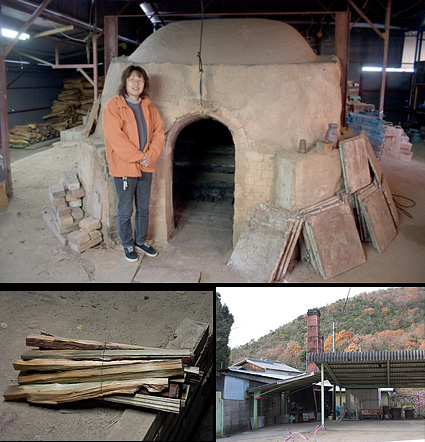

Gorobee kiln The panels stacked up against the side are used inside the kiln as shelves, creating various levels for different firing results.

|

Here we can see pots stacked on three different levels. The pots will all have a different finish depending on where they are placed. On the top level it is possible to get a natural glaze, wheras pots placed in the bottom are covered with ash. Photo : Gorobee kiln |

|

Pots being fired inside the kiln. Photo : Gorobee kiln |

class="style2"> This pot was fired at the bottom of the kiln. The round spot design is created by placing clay discs with a different firing temperature on the pot prior to firing.

Photo : Gorobee kiln |

Mr. Suzuki Tsuneki after Kamataki.

He now fires only once a year in December. The firing takes two weeks but the whole process from preparing to cleaning up takes up to a month to complete.

|

|

Ms. Mimura Kimiko of Tohaku kiln

|

|